Your build files are ready, your build plate is clean and, after researching and deal hunting, you’ve taken the plunge with the best 3D printer around. But all of that careful preparation can come to cloggy, stringy, flailing halt if you choose the wrong filament for the job.

Filament is the material we use for FDM 3D printing, and it’s easy enough to find. But there are different filament types, and while they can all print the same project files, minor differences can lead to major quality changes in the finished creation. Certain filaments also need certain precautions or printer requirements. You’ll want to ensure you’re using the best filament for the job.

What is the best 3D printing filament?

Almost everyone who uses a 3D printer uses PLA for most of their prints. You might use other materials for certain things, but day-to-day printing is likely done with PLA. The best PLA for most use cases is Build Series PLA from MatterHackers. I’ve used over 100 kilograms (220 pounds) of it by now, and it’s still my favorite. It sands very well and prints easily on just about any FDM printer.

I’ve put together this primer on different types of filament, including the best PLA filament, as well as choices of the best filaments from my favorite brands. This will be updated regularly and has some great choices to help you start. I use around 8 kilograms (17.5 pounds) of filament each week — and have for the last four years — so I know I’m offering you the best options around.

It’s important to choose both the right type of material and the right brand of that type, be it PLA, ABS or something more exotic. Here are the best of each of the five main filament types.

Read more: Best 3D Printers

PLA is the easiest material to use to make awesome things.

Polylactic Acid (PLA)

Polylactic acid, or PLA, is the most common 3D printing filament, and it’s the easiest to use. Unlike most plastics, it’s made from corn starches so it’s nontoxic and, in theory, compostable, though it takes an industrial composter to do it. PLA uses a fairly low heat — between 190 and 215 degrees Celsius (374 and 419 degrees Fahrenheit) — to melt the plastic for extrusion, so it is the safest of the filaments. Almost every FDM 3D printer in the world can print PLA.

PLA pros

- No awful smell

- Easy to use for a beginner

- Almost universally available

- Nontoxic

- Usable on any FDM printer

- Cheap

PLA cons

- Can require a lot of sanding

- May warp in the sun or high-temp environments

- Can be brittle

Build PLA from MatterHackers is great for projects that require finishing (sanding, painting and so on). I have about 12 rolls of it in my workshop and use it for large projects, including my Mandalorian armor or cosplay swords. The dimensional accuracy — how consistent the diameter is along the length of the roll — is good, though nothing mind-blowing. It’s well within the sweet zone.

Post-processing is where Build Series PLA shines. It is simple to sand and holds paint well, as long as you use a good primer and filler first. Like all PLA, it holds together well using superglue and even takes putty and Bondo without complaint.

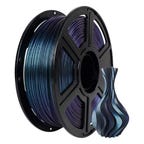

The color of this PLA is hard to describe, but it is beautiful. It has a purple-blue-green hue and looks like metal that’s been heated up. Right now, it’s probably my favorite-looking filament.

It’s also easy to print with, and because of the shifting colors, it hides layer lines well. If you’re looking for a dark filament that you aren’t painting over, I’d pick up a few rolls of this today.

I really enjoy the color of this PLA from Inland. It prints very well and the shimmer from the gold/red highlights hides any layer lines after it has printed. Beautiful colored filament always makes me happy, and this is one of my favorites.

With the advent of ultra-fast 3D printers, companies including Elegoo have started to create materials that work better at high speeds. Rapid PLA Plus works extremely well at high speeds due to its high fluidity when melted. It printed very well on several of my fastest machines and sands very well if you are looking to finish your prints with paint.

Ataraxia Art already makes excellent PLA and flexible PLA, but its new range of tri-color filament is some of its best yet. Tri-color uses three colored filaments along its width to create a beautiful shimmering effect as you move the model, so it’s perfect for projects you aren’t going to be painting.

This PLA comes in four different color combinations and is one of my favorite filaments to use.

I’ve been meaning to buy some of this beautiful filament for some time now, and I’m really happy I did. The color is almost exactly the same as mint chocolate chip ice cream, and the tiny flecks of marble color enhance the look even more. It prints great, with a nice glossy finish, and I found printing it at a higher temperature brings out that gloss really well.

Aside from the print quality, I love the way it makes me feel. The color just makes me happy and reminds me of days at the beach with my kids. It’s gorgeous.

Rainbow filament tends to transition between colors very slowly. This means you often get only one or two colors per model. Creality’s latest rainbow filament has a much shorter transition, so you get a much nicer rainbow effect across your models. It looks great on this amazing dragon from Fotis Mint.

For projects you can show off without paint, PolyTerra might be for you. The colors are vivid, and because they are matte, you don’t lose details in the reflections like with shiny filament.

PolyTerra also comes in recycled cardboard reels, and the creator, Polymaker, will plant a tree in the area where the roll was bought to help offset the cardboard used. This filament is still plastic, but it helps my conscience to use this one.

In an article about this flexible PLA, I explained how, although this isn’t technically PLA, it does print much easier than TPU, a more common flexible filament. I used it to print an amazing Mandalorian Blacksmith helmet for my 4-year-old. She can’t break it because it’s so bouncy.

This isn’t for newbies, though. It took a lot of trial and error to get the setting for my 3D printer right, and because it is so soft, the accuracy can be pretty wonky. But for something that’s different from normal PLA, it’s worth checking out.

ABS was one of the more common 3D printing filaments a few years back, and it still has some excellent uses. The biggest downside is toxicity. You don’t want to breathe in ABS as it melts, so you’ll need a well-ventilated area. That aside, it’s sturdier and more heat-resistant than PLA. Most printers can print ABS, but you’ll need a heated bed that can reach 100 degrees Celsius (212 degrees Fahrenheit) for best results, and protecting your printing job in an enclosed printer is a good idea.

ABS pros

- Can withstand a lot of heat

- Easy to sand

- Can be smoothed with acetone for a perfect shine

ABS cons

- Fumes are toxic, so it requires ventilation

- Needs far more heat to print than PLA

- You will need an enclosure to get good results

Inland makes good filament across the board, and its ABS is no different. I’ve never had issues with the dimensions, and the final product has consistent layer lines. Sanding Inland ABS is a joy as the material can be wet-sanded to a smooth finish.

Fillamentum is one of my favorite ABS makers. The colors are always so vibrant, and while it costs a little more than the competition, it keeps that vibrancy even after the model is finished printing. If you’re looking for ABS that you don’t need to paint, Fillamentum is a great place to start.

PETG is chemically similar to the plastic that water and soft drink bottles are made of, and it’s a great alternative to ABS. It has the heat-resistant properties of ABS without the toxic fumes and can be sanded much like PLA. Most FDM printers that can print PLA can print PETG, though it takes a little more effort to get right.

PETG pros

- Easier to print than ABS

- Holds a finish well

- Easier to store than other filaments

PETG cons

- Requires high temps, which can damage printer parts over time

This US-made PETG has an excellent glassy look that is hard to achieve in melted plastic. The aqua color is subtle and gives the appearance of a stained glass window when printed at the high end of its temperature scale.

Printing with it was easy, though the roll is a little big for printers like the Bambu Lab X1, which has an enclosed filament system.

Overture PETG is a favorite because it comes in an economical two-pack, making it ideal for multiple or larger jobs. I’ve used a lot of Overture products, including PETG and PLA, and they always print well. I once printed an 11-foot-long Masamune sword using Overture and it came out looking awesome.

The Pro series filament from MatterHackers is a much nicer product than a lot of standard PETG. Yes, it costs a little more, but it’s designed to help reduce some of the issues that filament suffers from. It reduces shrinkage, so the part you make is as close to the part you designed as possible. This is a great material for those who make 3D-printed models for a living rather than a hobby.

TPU is a flexible material that can make cool rubbery models. Most people use it to 3D print phone cases, but more serious modelers often use it to create connectors or flexible hinges to other materials. It can be a difficult material to work with and is best used on a direct-drive 3D printer such as the Prusa Mk4, and it’s worth noting that TPU does not work with the AMS system from Bambu Lab.

TPU pros

- Flexible

- Won’t warp in the heat

- Available in fun colors

TPU cons

- Terrible for making solid prints

- Hard to work with on budget printers

MatterHackers Build Series Materials perfectly balance usability and cost. Yes, I’ve had failures with the Build Series, but once you get it dialed into your printer, you can make dozens of fun, springy models.

I like to use it to make fun toys for my kid’s preschool — they can be thrown around without breaking into small, sharp pieces.

There is so much to love about this TPU from Inland. It’s colorful, and the rainbow transitions look beautiful. It’s flexible and can be used as a phone case. And it’s almost translucent, so it has a glassy look. It is great for projects that need to stand out.

Exotic filaments

Glow-in-the-dark filament normally comes in a standard “radioactive” green, but this beautiful roll transitions through multiple colors. It’s simply gorgeous.

It’s also worthwhile to buy some replacement brass nozzles for your printer. Glow-in-the-dark filament can chew them up pretty quickly because the glowing material is more abrasive than standard colors.

This filament isn’t the cheapest, but it is fascinating. This PLA has dense iron powder mixed into it so it is magnetic, and it can rust if you spray it with salt and vinegar. Being able to easily print any model as normal and then rust it allows you to create some brilliant effects.

What filament should I start with?

Are there different sizes of filament?

Does the filament keep the same color after printing?

Having the right diameter makes for a better print.

Testing focuses on a few details: Dimensional accuracy, winding precision, and printing quality. Winding precision is a visual test where I check to make sure the filament works well on the spool, without any crossovers that can cause snags while printing.

Print quality is done using a CNET calibration test that I use to test all of the 3D printers I review. When checking for filament quality, I’m looking for noticeable roughness and missing filament where moisture or other contaminants have interrupted the process of melting and cooling.

Dimensional accuracy is perhaps the most important test as it measures the consistency of filament. As you move along, the filament changes in diameter and will cause the 3D printer to over- or under-extrude filament. This creates noticeable scarring in your model, or worse, complete failure. You want the material to have the same diameter the whole way through.

To measure the accuracy, I take a 5-meter (16.4-foot) piece of filament from the beginning, middle and end of the roll and measure the diameter at four equally spaced points. I then add up all of those measurements and divide the total by 12 — the total number of measurements taken — to give me an average across the roll. Most modern printers use 1.75mm filament, so you want the filament to be as close to that as possible.

Great filament has a variance of plus or minus 0.02mm, good filament is plus or minus 0.03mm and rough filament is anything plus or minus 0.05mm. All of the filaments we have recommended here are at least 0.03mm on average.

synnbiob

synnbiob